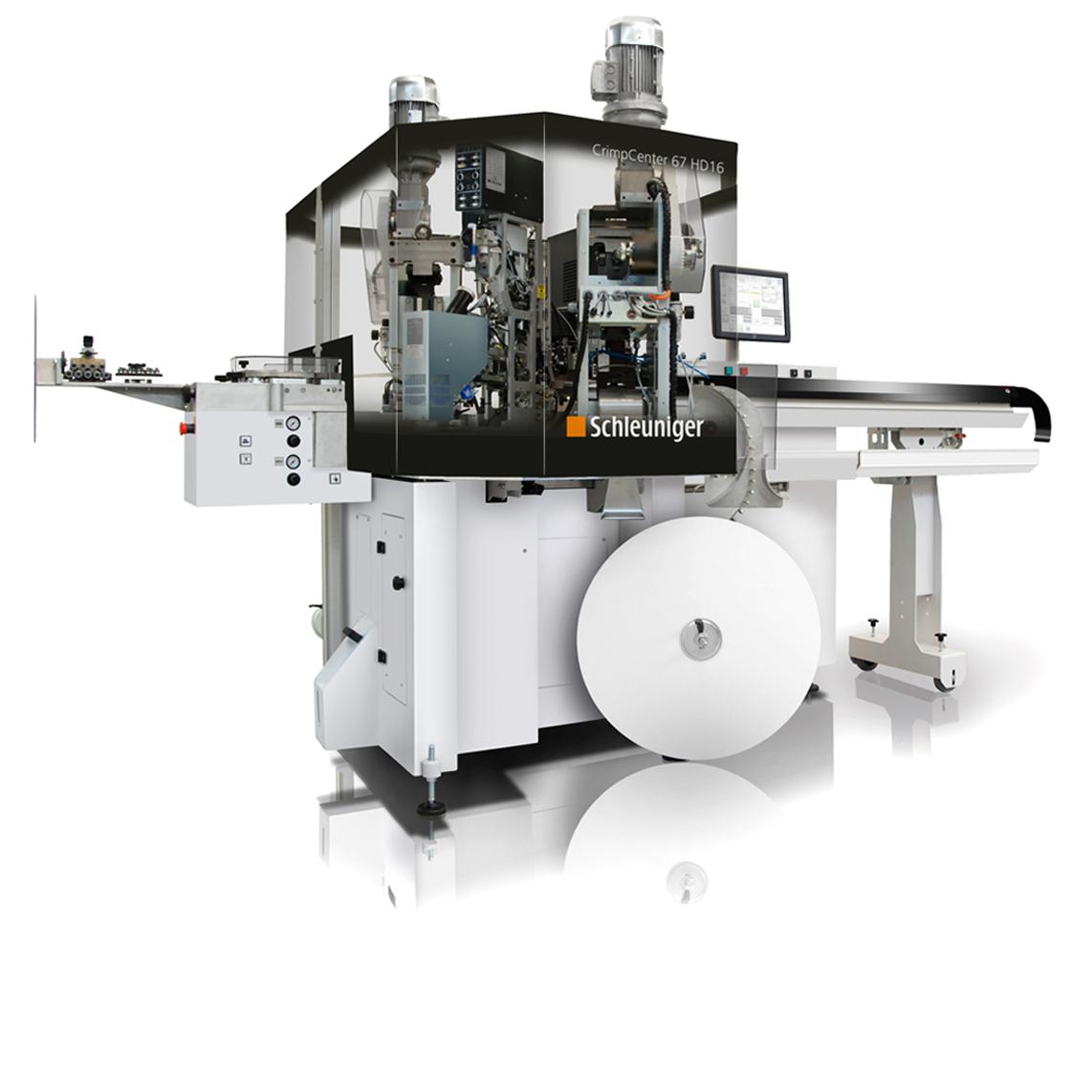

CrimpCenter 67 HD16

Fully Automatic Crimping Machine

Overview

The CrimpCenter 67 HD16 is a fully automatic swivel arm crimping machine with up to 4 processing stations. It is ideally suited for medium to large cable applications from typically 6 to 16 mm² (10 - 6 AWG). At a maximum feed rate of up to 12 m/s (39.4 ft/s), this versatile fully automatic crimping machine allows high-quality crimping, sealing and twisting of wires at maximum productivity.

- Production of larger cables up to 16 mm² (6 AWG)

- High performance and short set-up times

- Simple operation with state-of-the-art software and touchscreen

- Easy network integration

- Wide range of options and accessories available

Application Range

The CrimpCenter 67 HD16 is a heavy-duty, fully automatic crimping machine for up to four processing stations designed for maximum speed, flexibility, precision, fast changeovers and long-term durability. Various configuration possibilities allow for a variety of applications to be processed. Dynamic and powerful servo drives combined with an intelligent control system provide high production rates to meet the most demanding production schedules. Production parameters are entered via touchscreen. The intuitive, menu-guided graphical user interface reduces staff training time and minimizes entry errors. All parameters such as wire data, crimp data or seal data can be saved and retrieved for future use. Electronic documentation, including operating instructions, spare parts identification drawings and schematics, are all stored electronically in the machine software for immediate access when needed.

Processing Capabilities

Technical Data

| Processing Stations | 4 (maximum 2 crimping stations) |

| Workpiece Length | 55 mm – 65 m (2.17” – 213 ft) |

| Strip Length | Side 1: 0.1 – 18 mm (0.004 – 0.71”) Optional up to 26 mm (1.02”) |

| Conductor Cross Section | 6 – 16 mm² (10 – 6 AWG) |

| Feed Rate | Maximum 12 m/s (39.4 ft/s) |

| Dimensions (L x W x H) | 3,740 x 1,800 x 2,500 mm (147 x 70 x 98”) |

| Height (Safety Cover Opened) | 2.85 m (112”) |

| Weight | Approx. 750 kg (1,653 lbs.) Incl. base machine and safety cover Approx. 1,150 kg (2,535 lbs.) Max. incl. processing stations and options |

| CE Conformity | The CrimpCenter 67 HD16 fully complies with all CE and EMC equipment guidelines relative to mechanical and electrical safety and electromagnetic compatibility. |

More Info

Processing Stations

Processing stations communicate via TCP/IP for short internal communication times and flexible configuration.

- UniCrimp 500 A Crimping station with optional crimp force monitor

- SLU 3000/3100 Seal loading stations with various seal monitoring options

- Custom station integration of 3rd party products for various processing capabilities and QA devices.

Increase Productivity

With feeding speeds of up to 12 m/s (39.4 ft/s), fine-tuned swivel arm movement, optimized internal communication, and fully integrated processing stations, CrimpCenter machines offer unparalleled levels of performance for today’s most demanding applications. To minimize machine downtime, the CrimpCenter 67 HD16 utilizes quick-change mechanisms so that wire guides, blades and feed belts can be quickly changed without the use of tools. To further optimize production, the CrimpCenter 67 HD16 can be easily integrated in any network with standard TCP/IP. The optional EASY ProductionServer software can be used to network all of your CrimpCenter machines and allows central management of production orders and distribution of the orders to individual CrimpCenter machines.