CrimpCenter 36 SP

Fully Automatic Crimping Machine

Overview

The CrimpCenter 36 SP offers decreased setup time and increased effective performance. Therefore, overall productivity is increased and jobs can be processed in less time. Furthermore, new features improve quality by systematic optimization, automating previously manual processes and enhancing wire handling. The end result is that the CrimpCenter 36 SP will help you achieve your targets in less time while decreasing cost per lead.

- Optimized default parameter settings

- A newly developed deposit gripper system

- Improved synchronization of the feeding unit and conveyor

- Increased feeding speed from 8 m/s to 10 m/s

- Additional wire guides at the machine entrance

- Improved wire straighteners

- Automatic pressure adjustment

- Automatic slider tray

Application Range

The CrimpCenter 36 SP processes wires from 0.13 mm² to 6 mm² (26 AWG – 10 AWG) and features all of the latest quality assurance options such as SmartDetect, WireCam and the Guided Feasibility Study. These features, along with the attractive price point, make the CrimpCenter 36 SP an excellent machine for complex and high precision production with high-quality targets.

Material

- Single Wire

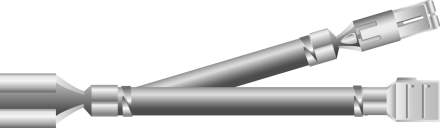

Processing Capabilities

Technical Data

| Processing Stations | Maximum 6 (maximum 3 crimping stations) |

| Workpiece Length | 55 mm – 65 m (2.16” – 213') |

| Strip Length | Side 1: 0.1 – 18 mm (0.004 – 0.71”) |

| Conductor Cross Section | 0.13 – 6 mm² (26 – 10 AWG)* |

| Raw Material Diameter | Maximum 4.7 mm (0.18") |

| Feed Rate | Maximum 10 m/s (32.8 ft/s) |

| Power Supply | 3 / N / PE AC 210 500 V; 50 / 60 Hz; 16 A |

| Compressed Air Connection | 6 bar (90 psi), non-oiled, dried and filtered compressed air |

| Dimensions (L x W x H) | 3,363 x 1,428 x ca. 2,155 mm (132” x 54” x 85”) / 2 m base |

| Height (Safety Cover Opened) | approx. 2850 mm (112”) |

| Weight | approx. 440 kg (970 lbs.) incl. base machine and safety cover |

| CE Conformity | All CrimpCenter models complies with all CE and EMC equipment guidelines relative to mechanical and electrical safety and electromagnetic compatibility. |

| Important Note | Schleuniger recommends that wire samples be submitted in cases where there is doubt as to the processing capabilities of a particular machine. * Wires with hard insulations or those that are tightly bonded might not be able to be processed even if they are within the application range stated above. For cross sections smaller than 0.22 mm² (24 AWG) and larger than 4 mm² (12 AWG), sample processing is required. |

More Info

Processing Stations

- UniCrimp 221 Crimping station with integrated CFM 20

- UniCrimp 222 Crimping station with integrated CFM 20 and electronic crimp height control

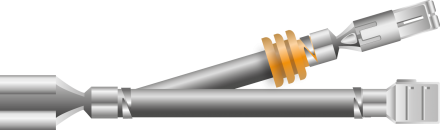

- SealLoad 3100 and SLU 3000 Seal loading stations

- SLD 4100 Double gripper module

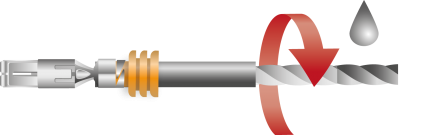

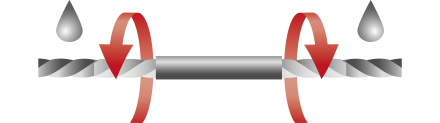

- STW 1100 Twisting station

- STS 1100 Tinning station

Options

- SmartDetect

- WireCam

- Material Change Detection

- Guided Feasibility Study

- Two-wire wire straightener unit

- EASY ProductionServer software

- Extension conveyors

- Integrated quality assurance devices

- Prefeeding systems