Strip Series B340

Stripping Machine

Overview

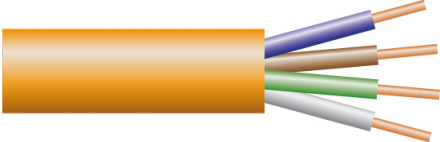

The Strip Series B340 stripping machine boasts a wide range of performance. Equipped with four rotary X-shaped blades, it processes simple stranded wires and multiconductor cables with a cross section from 0.013 to 16 mm² (36 – 5 AWG) and a diameter of up to 9 mm (0.35”), thus achieving a strip length of 80 mm (3.15”) and a pull-off length of 40 mm (1.57”).

Repeat accuracy, mechanical precision and short work cycles ensure high productivity. The blades and universal clamping jaws on the Strip Series B340 can be used across the entire range of cable processing applications – machine downtimes due to changeovers are eliminated.

The focus on ergonomic operation and programming via a 5" color touch screen with good accessibility further increase productivity.

The Strip Series B340 is quick to deploy and is extremely easy to operate without programming knowledge thanks to its state-of-the-art, user-friendly software interface.

Application Range

Material

- Cable

- Wire

- Single-Conductor Cable

- Solid Wire

- Kapton

- Discrete Wire

- Multiconductor Cable

- Teflon®

- Stranded Wire

- Textile glass braiding

Processing Capabilities

Technical Data

| Conductor Cross Section - Strip | 0,013 – 16 mm² (36 – 5 AWG) |

| Raw Material Diameter | Max. 9 mm (0.35”) |

| Strip Length | Max. 80 mm (3.15”) |

| Pull-off Length | Max. 40 mm (1.57”) |

| Power Supply | 100 VAC to 240 V AC, 50/60 Hz |

| Dimensions (l x w x h) | 521 x 132 x 317 mm (20.51”x 5.19” x 12.48”) |

| Weight | 12 kg (26 Ibs.) |

| Declaration of Conformity | The Strip Series B340 fully complies with the CE and EMC machinery directives relating to mechanical and electrical safety and electromagnetic compatibility, as well as UKCA, UL, and CSA |

More Info

Options

- Kit for multi-conductor cables involving short jacket strips, with minimized distance between protective hood and blade axis

- Foot pedal

- Carbide blades for yielding and tough insulation

- Air kit with or without waste extraction system

Features

- No blade change for all processable cables

- No mechanical adjustments for changing the cable

- Processing parameters in mm² and AWG

- Sequential processing of multi-conductor cables, including jacket and inner conductor stripping in programmable sequence

- Optional kit for multi-conductor cables involving short jacket strips

- Barcode scanner function

Programmable processing parameters, including

- Strip and pull-off length

- Incising diameter

- Blade opening before pull-off (pull-off opening)

- Clamping force

- Twisting parameters