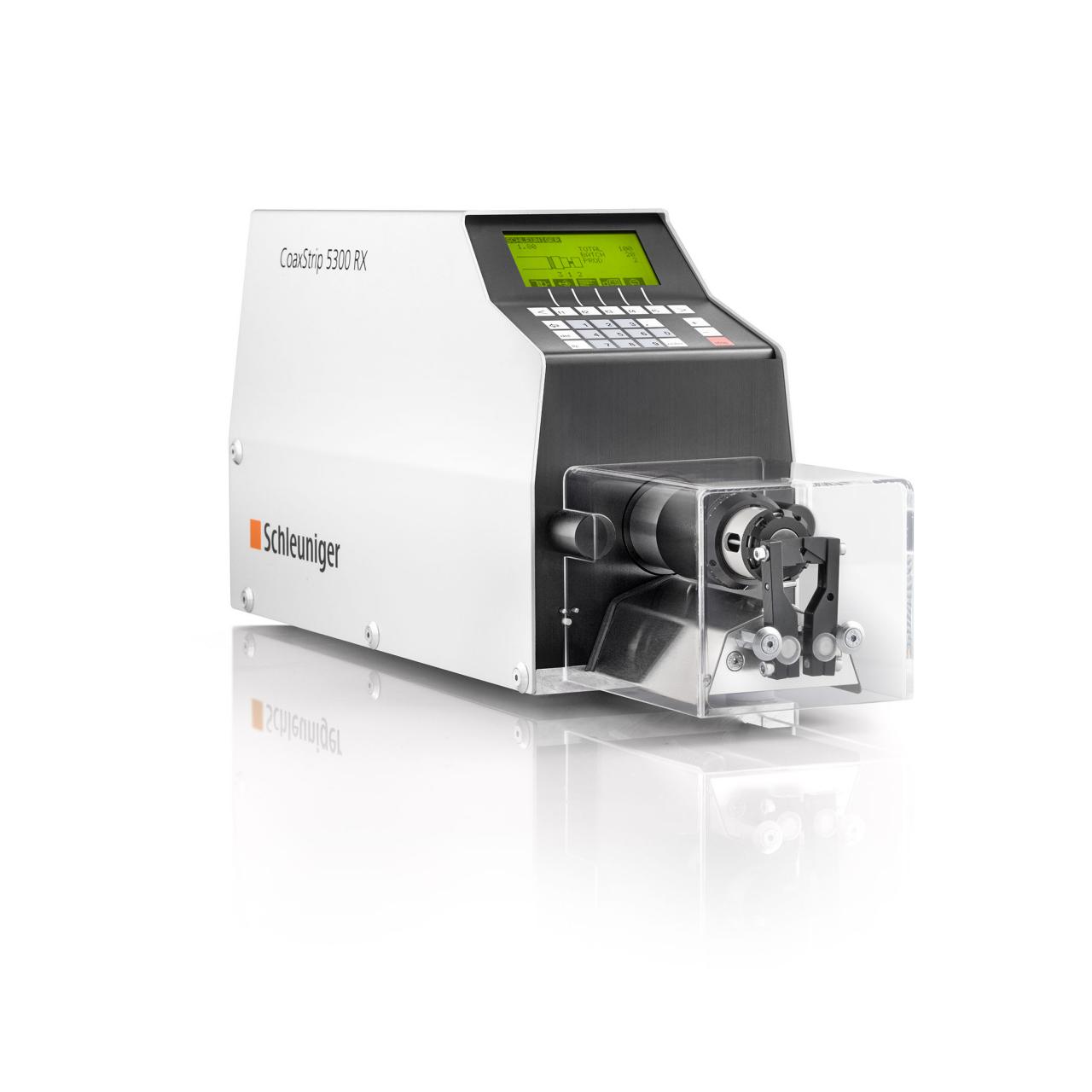

CoaxStrip 5300 RX

Microcoaxial Cable Stripping Machine

Overview

The CoaxStrip 5300 RX allows you to quickly and accurately strip wires and cables that would be virtually impossible to strip by hand, with inner conductors ranging from 0.07 mm (0.003''/42 AWG) up to 1.8 mm (0.070'') maximum cable outer diameter at a maximum stripping length of 29 mm (1.14").

Application Range

The CoaxStrip 5300 RX strips extremely thin micro coaxial cables down to inner diameters of only 0.07 mm (0.003''/42 AWG) at very short cycle times. Its new high-speed rotary stripping head design guarantees maximum precision and prevents maintenance-related machine downtime. Today, they are common in the medical industry and in antenna-related components or devices from different industries. Consequently, high quality standards regarding accuracy and reliability must be met during processing.

Material

- Wire

- Solid Wire

- Cable

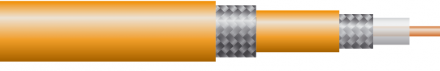

- Coaxial Cable

- Multiconductor Cable

- Single-Conductor Cable

- Microcoaxial Cable

- Rubber

- Discrete Wire

- Stranded Wire

- Paper / Cardbord

- PUR

- PVC

- Teflon®

- Tefzel®

- Kapton

Processing Capabilities

Technical Data

| Outer conductor diameter | Max. 1.8 mm (0.070") |

| Inner conductor diameter | Min. 0.07 mm (0.003"/42 AWG) |

| Diameter Increments | 0.01 mm (0.001") |

| Strip Length | Max. 29 mm (1.14") |

| Strip Length Increment | 0.01 mm (0.001") |

| Stripping Steps | Max. 9 |

| Clamping | Motor driven with programmable clamping force |

| Production Rate | 600 pcs. / hour (depending on cable type and programming) |

| Memory Capacity | 1,000 cables / 100 wire lists |

| Interfaces | RS 232, foot pedal |

| Noise Level | <70 dB (A) |

| Power Supply | 100 / 240 VAC: fuse 3.15 A/T, 50/60 Hz, 100 VA |

| Compressed-Air Connection | 4 - 6 bar (60 - 90 psi) |

| Dimensions (L x W x H) | 494 x 140 x 218 mm (19.4" x 5.5" x 8.6") |

| Weight | 9 kg (20 Ibs.) |

| CE Conformity | The CoaxStrip 5300 RX fully complies with all CE and EMC equipment guidelines relative to mechanical and electrical safety and electromagnetic compatibility. |

More Info

Programmable Processing Parameters

- Pull-off with or without rotation of the stripping head

- Pull-off speed

- Stripping lengths partial strip

- Stripping lengths full strip

- Extra spin time of the stripping head

- Spindle direction of the stripping head

- Rotational speed of the stripping head

- Stripping diameter

- Stripping Position

- Wayback (opens blades slightly before pulling off)

- Feed rate of the stripping blades

- Cable clamping force

Features

- Wire list processing

- IGUANA Wire Processing Software (optional)

- Diagnostics features

- Password protection with different user levels

- Equipped with waste vacuum system (to prevent maintenance-related machine downtime)

- High output rates with highest precision