CoaxCenter 6000

Unbeatable Quality in Microcoaxial and Coaxial Cable Processing

Overview

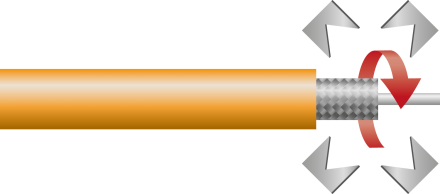

The CoaxCenter 6000 is the world’s first machine that can process micro-coaxial and coaxial cables as well as single-conductor wires fully automatically and with high precision.

Consequently, the range of applications is in line with the latest trends in automation, miniaturization, information and communication technology, and mobility.

The machine platform can be individually fitted with up to six processing stations. Stripping is carried out using the RotaryUnit 6000 or using V-shaped blades with multi-blade heads. The blades and cable guides are designed so that the cable is optimally held in position during processing, without being damaged by the clamping pressure. Stripped cable parts are disposed of by a powerful extraction system.

The cable end is held by a single gripper during all processes. It retains its exact position and is fed to the individual stations with maximum positioning accuracy.

The quality of the process steps is inspected by the QCam 360 camera system. Stripped cable ends and the correct positioning of crimp terminals are continually monitored, and incisions and scrap stranded wire are detected. Reject parts are sorted out immediately.

The CoaxCenter 6000 portfolio is rounded off by unique processing modules such as a centrally closing crimping press for very small and delicate crimping applications from 0.013 mm² to 2.5 mm² and a fully programmable chamfering station for solid wire inner conductors. Thanks to the open machine concept, processing stations from third-party suppliers can also be integrated into the platform.

The CoaxCenter 6000 is characterized by short changeover times as well as fast and simple machine setup. This is ideal for highly productive shift operation. The simultaneous processing of both cable ends and the extreme speed while maintaining absolute precision allow for unrivaled performance.

Application Range

Material

- Single Wire

- Solid Wire

- Coaxial Cable

- Microcoaxial Cable

- Semirigid Cable

- POF (polymer optical cable)

- Corrugated Cable

Processing Capabilities

Technical Data

| Processing Stations | Up to 6 stations |

| Raw Material Diameter | Max. 7.0 mm (0.27") with linear feed unit Max. 5.5 mm (0.21") with belt drive |

| Conductor Cross Section | 0,005 mm² – 2.5 mm² * (40 AWG - 14 AWG) |

| Workpiece Length | Approx. 15 mm to 1 km (0.59” - 39,370”) - extremely short cable lengths, depending on the application |

| Strip Length | Side 1: 0.1 mm (0.004“) - 58 mm (2.28") Side 2: 0.1 mm (0.004“) - 38 mm (1.49") |

| Feed Rate | Conveyor belt max. 5 m/s Linear feed unit max. 2.5 m/s |

| Dimensions (L x W x H), depending on machine configuration | Minimum: 1,722 x 900 x 1,442 mm (67.79" x 35.43" x 56.77") - height with open safety cover 2,177 mm (85.70") Maximum: 3,033 x 1,182 x 1,472 mm (119.40" x 46.53" x 57.95") - height with open safety cover 2,347 mm (92.40") |

| Weight | Approx. 450 kg, incl. basic machine and safety cover (992.08 lbs.) Approx. 630 kg, incl. six processing stations and options (1388.91 lbs.) |

| Power Supply | 100/120 VAC, 200/240 VAC, 800 VA, 50/60Hz |

| Compressed Air Connection | 6 bar (87 psi) non-oiled, dried and filtered compressed air Average 65 l/min, maximum 400 l/min Air hose 12/9 mm, max air hose length 10 meter |

| CE Conformity | The CoaxCenter 6000 complies fully with all CE and EMC equipment guidelines relative to mechanical and electrical safety and electromagnetic compatibility. |

| Important Note | Schleuniger recommends that wire samples be submitted in cases where there is doubt as to the processing capabilities of a particular machine. |

More Info

Processing modules

- TinningStation 3000 tinning station

- PointingUnit 6000 chamfering station

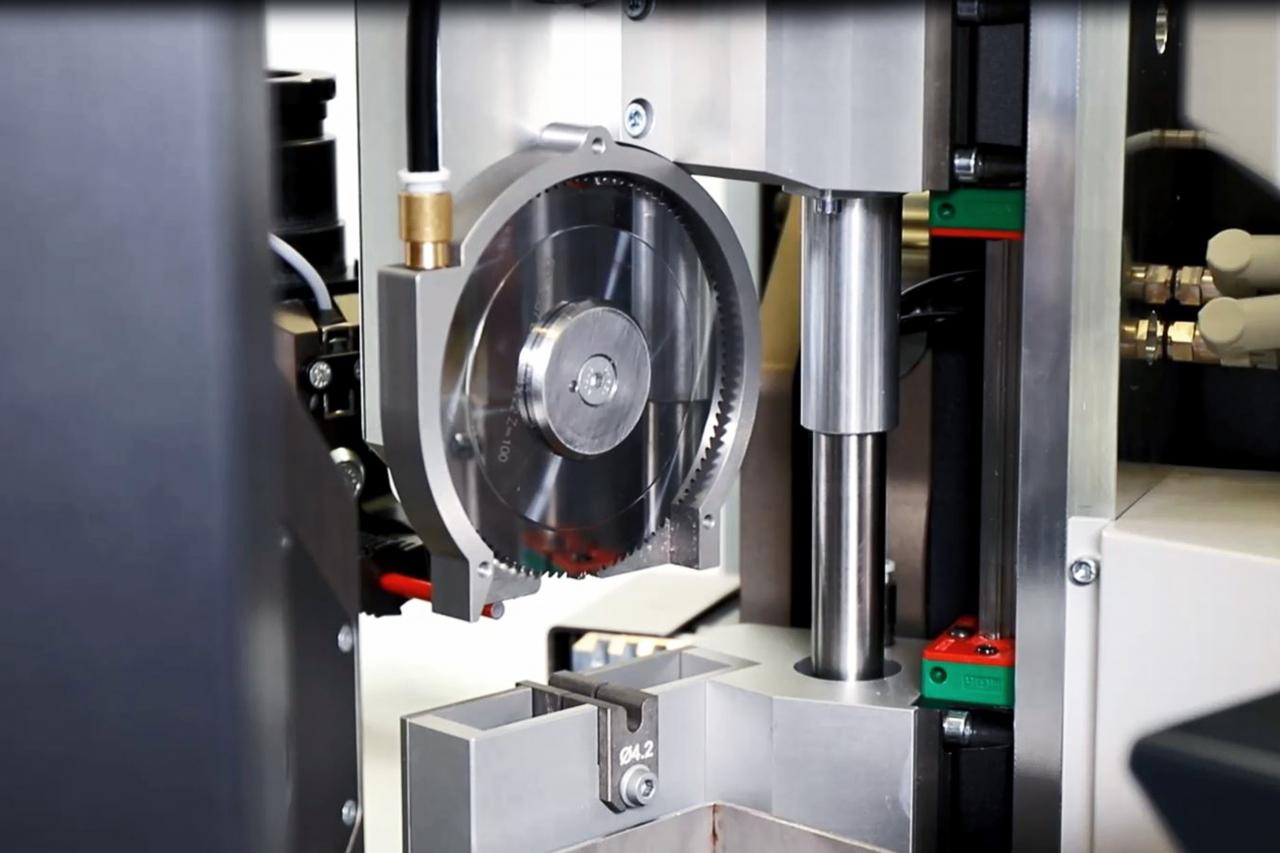

- CrimpPress 150 crimping station with optional crimp force monitoring (ACO 08)

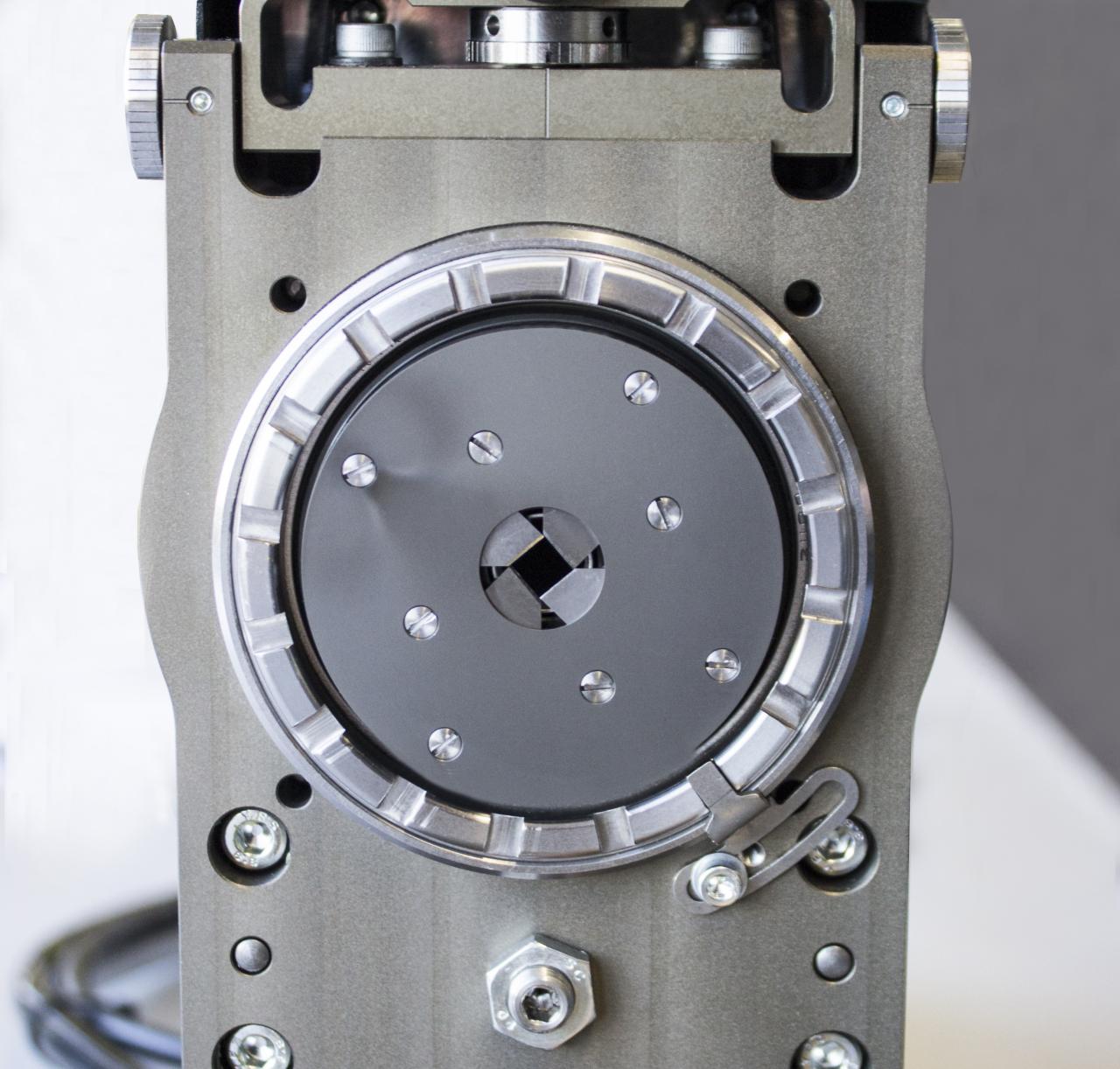

- RotaryUnit 6000 rotary cutting unit with integrated extraction system

- Sawing and cutting unit

- QCam 360 quality control system

- Linear feed unit

Options

- Barcode scanner

- RoboticInterface 6000 cable straightener

- Wire straightener unit

- Status light