Mercury-4

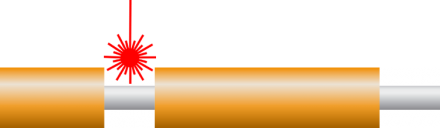

Laser Stripping Machine

Overview

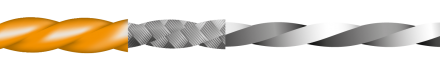

The Mercury-4 strips wires and cables ranging in size from 0.0010 to 16 mm2 (50 to 6 AWG). Using the color touchscreen, the operator selects the desired stripping parameters from the programmed library and all parameters (strip lengths, laser power and speed, etc.) are automatically set. Once the operator selects the required program, the machine is ready for operation. The Mercury-4 can strip cables inserted into the supplied fixture aperture to an end stop, or via a custom fixture plate. A camera allows the whole process to be monitored.

- High-quality, nick-free stripping

- Strips all polymer materials and colors

- Noncontact – no wear parts

- 0.0010 to 16 mm2 (50 to 6 AWG)

- Powerful and flexible processing capabilities

- 20 watt CO2 Laser

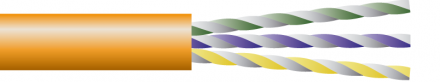

Application Range

Material

- Kapton

- Nylon

- Polyester

- Polyesterimid

- Polyethylen

- Polyimide

- Polyurethan

- PVC

- Silicon

- Teflon®

- Tefzel®

- Fiberglass

Processing Capabilities

Technical Data

| Conductor Cross Section | 0.0010 to 16 mm2 (50 to 6 AWG) |

| Raw Material Diameter | Maximum 6 mm (0.24"), other applications upon request |

| Strip Length | Minimum: 0.5 mm (0.02") |

| Slitting Length | Maximum 50 mm (2.0") |

| Length Increment | 0.1 mm (0.001") |

| Laser Beam Speed | Up to 80"/s (2,032 mm/s) |

| Lens | High speed, dual axis galvo scanners |

| Cycle Time | 2 s for most materials |

| Cycle Start | Via touchscreen or optional foot pedal |

| Operation Type | Circumferential strip, linear slit, ablation, any stripping pattern in a 50 x 50 mm (2 x 2") strip area |

| Raw Material Type | PTFE / Teflon, Tefzel, PVC, Polyurethane, Silicon, Kapton, Polyimide, Polyesterimide, Polyester, Fiberglass, Polyethylene, Nylon |

| Memory Capacity | Unlimited |

| Interfaces | USB, external trigger / busy |

| User Interface | 7" color touchscreen |

| Noise Level | <80 dB (A) |

| Power Supply | 100/115 VAC, 230/240 VAC, 1.5 kW / 50/60 Hz |

| Dimensions (L x W x H) | 500 x 150 x 560 mm (20 x 6 x 22") |

| Weight | 20 kg (44 lbs.) Bench unit: 20 kg (44 lbs) control cabinet |

| CE Conformity | The Mercury-4 fully complies with all CE, OSHA and FDA guidelines relative to mechanical, electrical and laser safety. Class 1 enclosure incorporating a Class 4 laser product. |

| Important Note | Schleuniger recommends that wire samples be submitted in cases where there is doubt as to the processing capabilities of a particular machine. To comply with health and safety requirements, air extraction must be provided when using any laser wire stripper. If this is not available in your factory, Schleuniger can provide air extraction systems to remove smoke, particles and fumes from the laser stripping area and return clean air to the room. For PVC applications, PVC specific extraction systems are available and should be used. It is the responsibility of the end-user to ensure that adequate fume extraction is utilized. |

More Info

Options

- Custom designed fixture plates

- Barcode job selection

- In-line cut & strip integration - unlimited strip length

- Foot pedal

- 30 watt laser

- 40 watt laser

- Fume extractor