SealCrimp 210 B ECO

Stripping, Sealing and Crimping Machine

Overview

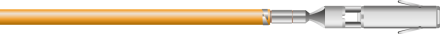

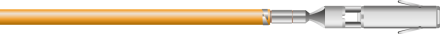

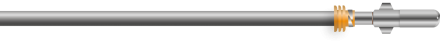

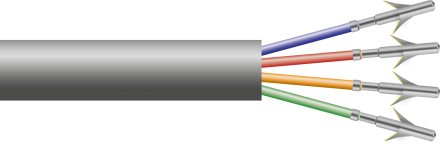

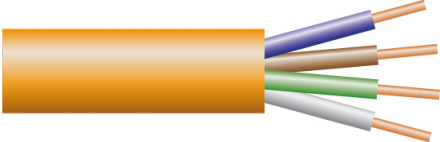

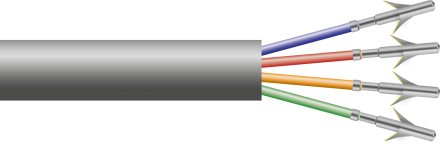

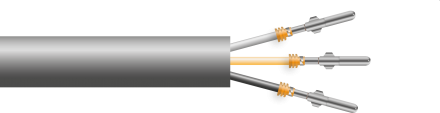

The SealCrimp 210 B ECO is a highly flexible benchtop machine for stripping, sealing, and crimping a great variety of different wire sizes up to 2.5 mm². The machine can process a great variety of crimp terminals and seal types including mini seals and hard-shell seals. Due to its modular design it can also be used as a stripper, stripper-crimper, or a crimping machine.

- High output

- Flexible use: selectable operating modes

- Short change-over times

- Precision & repeatability

- Simple operation

Application Range

The SealCrimp 210 B ECO is a benchtop machine for stripping, sealing and crimping wires. Designed to meet high quality requirements, the machine comes standard with crimp height fine adjustment, zero cut function and carrier strip cutter. Precision mechanics and reliable components guarantee high repeatability and short cycle times. Changing from one application to another is fast and simple with modular seal kits, a quick-change clamping system for crimp applicators and an exchangeable stripping cassette that can be equipped with either V-blades or die blades. Stripping, Sealing and Crimping can be selected individually. The order in which processes are executed is programmable. When inserting a wire, a sensor automatically triggers the machine cycle. Alternatively, the machine cycle can also be activated by using an optional foot pedal.

Processing Capabilities

Technical Data

| Conductor Cross-Section | 0.2 – 2.5 mm² (24 - 14 AWG) |

| Raw Material Diameter | Max. 6 mm (0.24“) |

| Breakout | 30 mm (1.18") |

| Crimping Force | 20 kN (2.0 ton) |

| Stroke | 40 mm (1.58“) |

| Seal Dimensions | Max. 10.5 mm (0.41“) outer diameter |

| Strip Length | Up to 8 mm (0.31“), adjustment in 0.01 mm (0.00039") increments |

| Power Supply | 1L / N / PE AC 230 V, 50/60 Hz, max. 0.9 kW |

| Compressed Air Connection | 6 bar (90 psi), oil-free, dry and filtered compressed air |

| Cycle Time | < 2 s Total cycle time for strip, seal, crimp |

| Dimensions (L x W x H) | 410 x 860 x 880 mm (16.1 x 33.9 x 34.6“) |

| Weight | Approx. 130 kg (286.6 lbs.) |

| CE-Conformity | The SealCrimp 210 B ECO fully complies with all CE and EMC equipment guidelines relative to mechanical and electrical safety and electromagnetic compatibility. |

More Info

Options

- SealCheck

- Ative terminal ejector

- Reject cutter

- Pilot

- Carrier strip cutter

- Paper Winder

- Interface for pneumatic crimp applicators

- SealClean 20

Features

- Short cycle times

- Broad application range for seals, cables and terminals (incl. hardshell

seals and mini seals) - Short change-over of seal kits (only 4 components)

- Selectable processing steps and programmable processing sequences

- Zero cut function, carrier strip cutter, crimp height fine adjustment

- Precise setting of strip length, incision depth and seal position

- The seal kit (track & pin) is compatible with the SLU