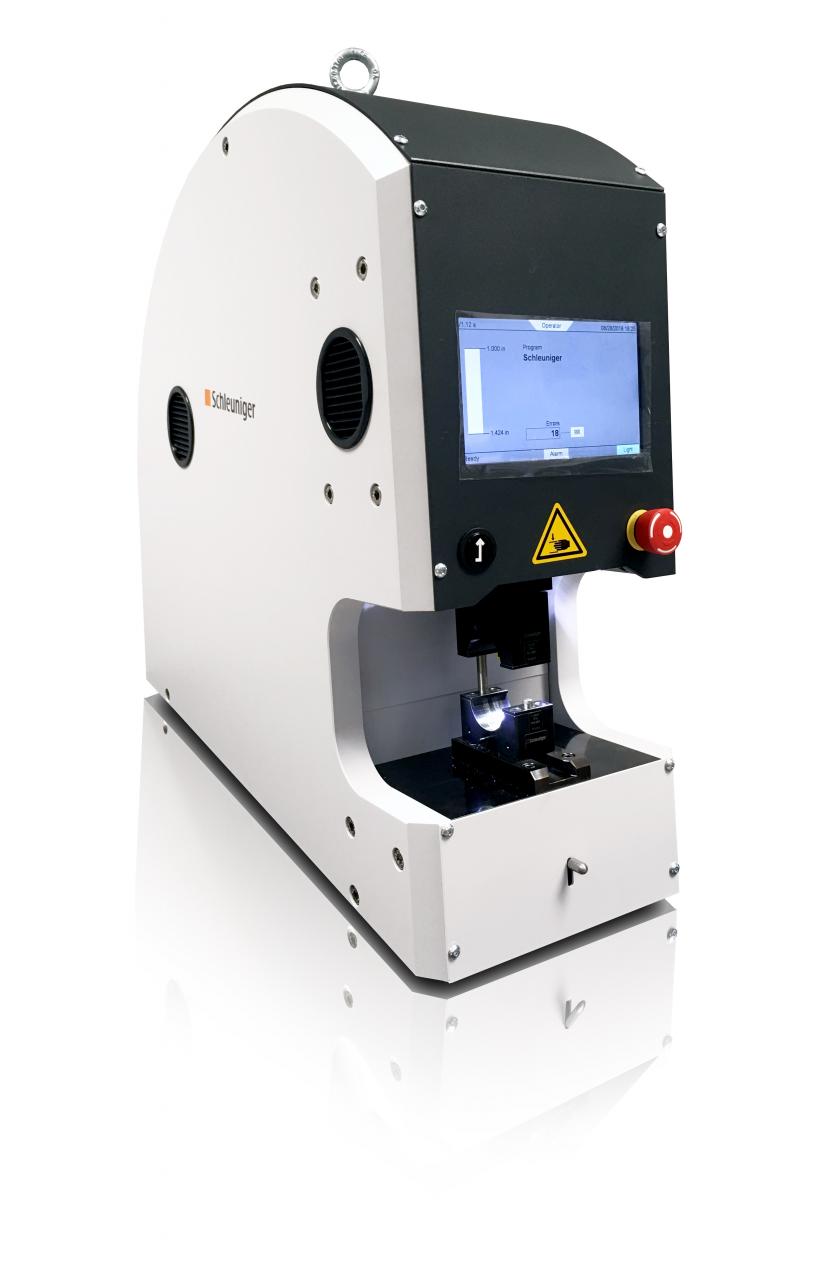

CT 150

Hydraulic Crimping Machine

Overview

The CT 150 hydraulic crimping press offers power, efficiency, and precision for heavy gauge, loose-piece crimping applications. Its parallel crimping action delivers up to 150 kN (16.9 tons) of force for applications for open barrel, closed barrel and heavy duty, 4-indent crimping applications.

Throughput is optimized by simultaneously minimizing the travel of the crimping head and an increased closing and opening speed. The fullcycle mechanism coupled with the integrated crimp monitor ensure high-quality output to adhere to even the most demanding specifications.

- Touchscreen interface for easy programming

- Programmable stop positions increases productivity.

- Integrated crimp monitoring and user authorization

- Flexible platform can accommodate a range of applications.

- Variety of crimp dies and adapters

- Quick-change die adapters

Application Range

A variety of crimp dies are available for the CT 150 for a wide range of applications. U-die adapters will accept some industry standard U-shaped crimping dies.

- Heavy duty

- Stamped and formed

- Closed barrel

- Preinsulated

Technical Data

| Crimping Force | 150 kN (16.9 tons) |

Conductor Cross Section Open Barrel |

Up to 150 mm2 (300 MCM) |

| Display | Touchscreen |

| Units (distance / pressure / temperature) | mm or inch / bar or psi / ºC or ºF |

| Programmable Increments | 0.01 mm (0.001") |

| Programmable Stop Positions | 3 |

| Crimp Force Monitor | Hydraulic pressure / monitoring parameters and crimp profiles saved with job |

| Memory Capacity | 100 Jobs |

| Remote Maintenance | Available via Ethernet |

| System Feedback/Diagnostics | Error list, Fluid temperature, Electronics temperature, I/O Status, I/O Response |

| User Levels | 3 (2 levels password protected) |

| Stroke | 40 mm (1.58”) |

| Ram Speed (Idle) | Down: 10 mm/s | Up: 12 mm/s |

| Cycle Speed | Approx. 7 seconds at full stroke (without back stroke limitation) |

| Safety Cover | Fixed around crimping dies |

| Activation | Foot pedal |

| Interfaces | Ethernet |

| Noise Level | 69 dB (A) |

| Power Supply | 110/230 VAC, 60 Hz |

| Dimensions (L x W x H) | 692 x 242 x 656 mm / 27.3 x 9.6 x 25.8” |

| Weight | 174 kg (382 lbs) / 194 kg (428 lbs) crated |

| CE Conformity | The CT 150 fully complies with all CE and EMC equipment guidelines relative to mechanical and electrical safety and electromagnetic compatibility. |

| Important Note | Schleuniger recommends that wire samples be submitted in cases where there is doubt as to the processing capabilities of a particular machine. |

More Info

The CT 150 features a touchscreen display for fast, simple programming and memory for up to 100 different jobs. The terminal hold capability promotes higher quality to ensure the connector is properly positioned and lets the operators move their hands from the crimping area.

The quick-change system allows for fast changeover times between a variety of optional die adapters. An array of crimp shapes and sizes are available to meet your applications.

User access levels ensure that only those authorized can make changes to job or quality information. System diagnostics provide feedback to aid in trouble shooting and resolving issues quickly.

Due to its open construction, a variety of crimping or pressing applications can be handled on this powerful, yet relatively compact press.